Home Terresis MAGNA

Terresis MAGNA

Refractory

Since 1945, we have been developing high value-added magnesium products and high-performance solutions. Thanks to our integrated mines in Spain and Brazil, our production factories and our technical and commercial teams spread worldwide, we have become the benchmark to support the steel sector in its development and anticipate the needs of tomorrow.

Fields of application

Our unique expertise in magnesia coupled with our in-depth knowledge of the field allows us to develop solutions adapted to the needs of the steel industry.

Products Tundish

Products for Distributors: Our solutions are divided into 3 main families – Spray (Tundimag), Dry Vibe (Filmag), and Self Setting (Coldmag) – Product ranges adapted for continuous casting dispatcher.

Bottom products

Our proven and recognized solutions – Basic refractory mass used for the construction of electric furnace hearth – Dry installation – Compaction with vibration in successive layers ensures the formation of a high-density, resistant monolithic layer during electric furnace campaigns.

Gunning

Our innovative solutions optimize the preventive and corrective maintenance of the slag line of furnaces and/or ladles.

Our innovative solutions

As close as possible to the needs of our customers, we have developed a range of high-performance solutions that combine magnesium products, cutting-edge technologies and tailor-made advice.

SELF-HARDENING

Coldmag : Enjoy a safe, clean and efficient solution for your distributors – drying without heating that allows pouring with all the guarantees, easy and clean.

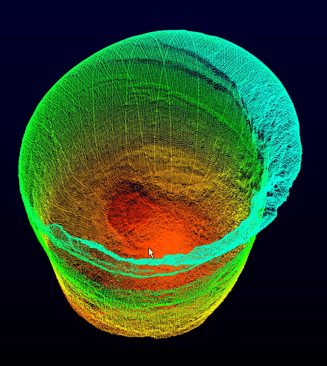

MAXI SURVEILLANCE

Visiomag : Remotely monitor the evolution of the refractory lining of your EAF furnace, identify damaged areas and anticipate your future interventions, in complete safety.

INCREASED ACCURACY

Connected robot : Enjoy high-speed gunning, a 360° rotating robot head and a vision camera for enhanced security.

Terresis, an integrated player as close as possible to the field

Unrivalled expertise for more than 80 years

Located in the heart of the territories and organized on a global scale, Terresis MAGNA benefits from a unique vertical integration: from extraction to production, including the development of tailor-made services, we are sized to meet all challenges.

Control of the value chain

From our magnesium carbonate extraction mines in Spain and Brazil, to the commercialization of magnesium solutions, we have complete control over every step, guaranteeing unrivalled quality and reliability.

Quality control

Continuous improvement and the quality approach guide each of our decisions, reflecting a high level of control from extraction to production. We are continually adjusting our practices to stay ahead of the curve.

Mastery of logistics

Our storage areas are located in the heart of international markets and our teams are located. As close as possible to the needs of our customers, we guarantee controlled deadlines, availability and regularity of supplies.

A technical team at the service of your performance

Much more than a producer and supplier, we are a true partner for the steel industry. Our technical experts from all over the world work at our customers’ sites every day to meet new challenges every day. Preventive and corrective maintenance of installations, but also optimization of equipment performance… They are extremely attentive and attentive to anticipate needs and take advantage of the exceptional potential of our solutions.

The vital role of magnesia

Thanks to its exceptional mechanical properties, magnesia defies the most hostile conditions to become an ally of choice in high-temperature industrial processes. In addition to remaining stable at more than 1,200 °C, it resists the attack of metals, even molten metals, and helps to maintain homogeneous firing, while protecting equipment, such as ovens, against thermal variations. That’s why, at Terresis MAGNA, we develop innovative magnesium solutions that support the steel sector in its transformation.