Home Terresis MAGNA Sole products

Sole products

The conditions of steel manufacturing are extremely demanding for furnaces. To ensure the integrity of the refractories, extend their service life and optimize production efficiency, high-performance refractories must be used, especially those capable of withstanding high stress.

The importance of refractory masses in furnace bottoms

Steel is produced using two main processes: the blast furnace route and the electric arc furnace (EAF) route. While their operation differs, the main distinction between these two furnaces lies in the raw materials used: the blast furnace route mainly consumes iron ore, coke and recycled steel, while the EAF produces steel via recycled scrap and electricity.

In both cases, extremely high temperatures and the prolonged contact with molten metal subject the furnace bottoms to high mechanical and thermal stresses. In the case of EAF, it is essential to apply a compact, dense and homogeneous refractory mass that offers optimal resistance to extreme heat, thermal cycling, as well as chemical attack and mechanical abrasion.

The role of magnesia in the construction of Electric Arc Furnaces (EAF)

To preserve the integrity of the of the EAF bottom – in the face of chemical and mechanical erosion caused by steel or scrap metal slag – magnesia is the only truly effective product: it offers excellent resistance to high temperatures, corrosion, chipping and thermal shock.

At Terresis MAGNA, we have developed a magnesium-based solution specially adapted for EAF bottoms. Formulated without additives and requiring no preheating, it allows the placement of a monolithic layer with high density. This refractory ramming compound guarantees excellent performance during melting operations, abrasion resistance and a barrier against the penetration of molten metal.

The role of magnesia in the construction of Electric Arc Furnaces (EAF)

To preserve the integrity of the furnace bottom – particularly in the face of chemical and mechanical erosion caused by steel or scrap metal slag – magnesia is the only truly effective product: it offers excellent resistance to high temperatures, corrosion, chipping and thermal shock.

At Terresis MAGNA, we have developed a magnesium-based ramming solution specially adapted to the bottoms of magnesium-based electric arc furnaces.

Formulated without additives and requiring no preheating, it allows the placement of a monolithic layer with high density. This refractory ramming compound guarantees excellent performance during melting operations, abrasion resistance and a barrier against the penetration of molten metal.

Solutions to preserve the integrity of furnaces

Every day, metallurgical furnaces are exposed to extreme thermal, mechanical and chemical stresses that weaken their structure. In addition to the refractory material used to build the bottom at campaign start or during a heavy repairs, it is recommended to regularly apply repair materials to extend the life of the campaign.

Magnesia-based products are particularly suitable for these extreme environments. They offer exceptional resistance to slag corrosion, low reactivity to liquid steel and excellent resistance to high temperatures. Applied hot, these materials allow for quick and targeted intervention, reducing downtime and optimizing furnace productivity.

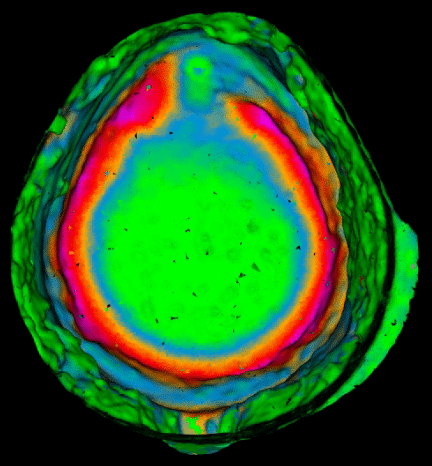

A unique piloting system

At Terresis MAGNA, we go one step further. In addition to our grooming masses and repair materials, we have developed an innovative monitoring system that allows us to monitor the development of the refractory lining in real time – and to measure very precisely via images – the evolution of the refractory lining. The key is a targeting of damaged areas, an optimized use of refractories, and the elimination of personnel in risk areas, for maximum safety.